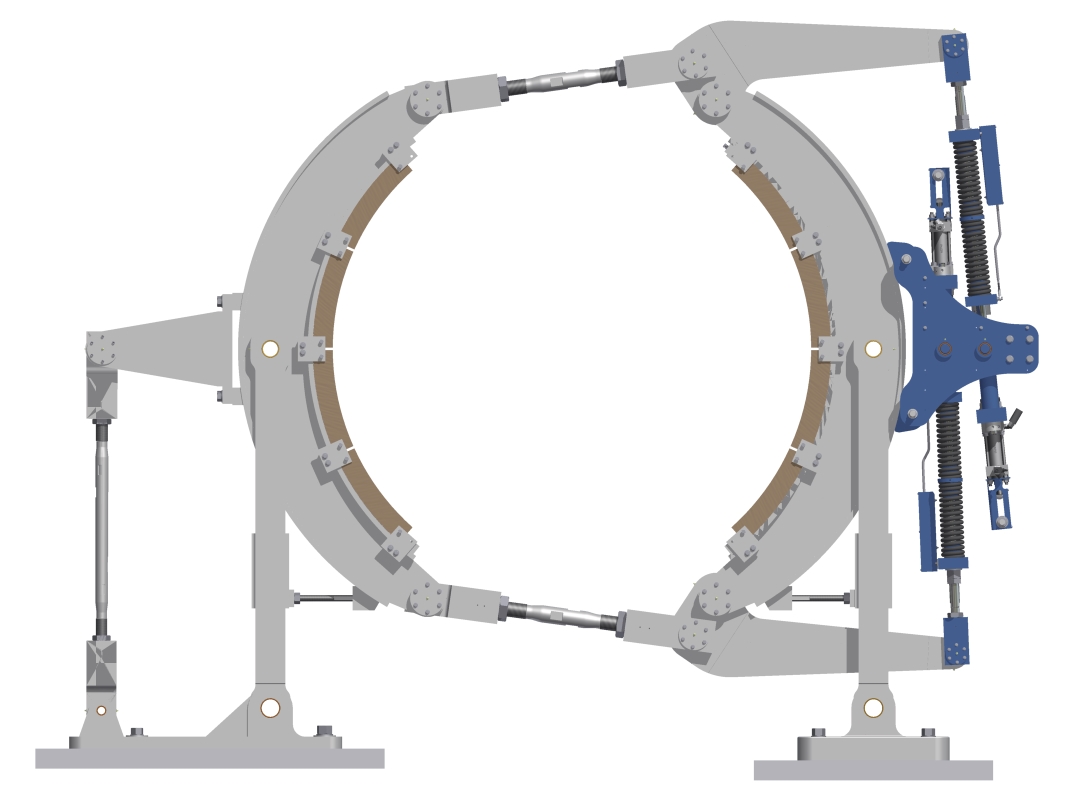

Hoist Bearing Lubrication System

Case Study: Replacement hydraulic bearing lubrication for plain bearings

Requirements: Replace a hydraulic bearing lubrication system to improve oil distribution and condition monitoring.

The new bearing lubrication system was designed to allow precise flow of oil to each individual bearing housing port and improve distribution across the face of the journal. Overall oil flow was increased to optimize wedge development and maximize bearing life. The system provided monitoring of overall oil flow as well as oil flow to each individual bearing port.

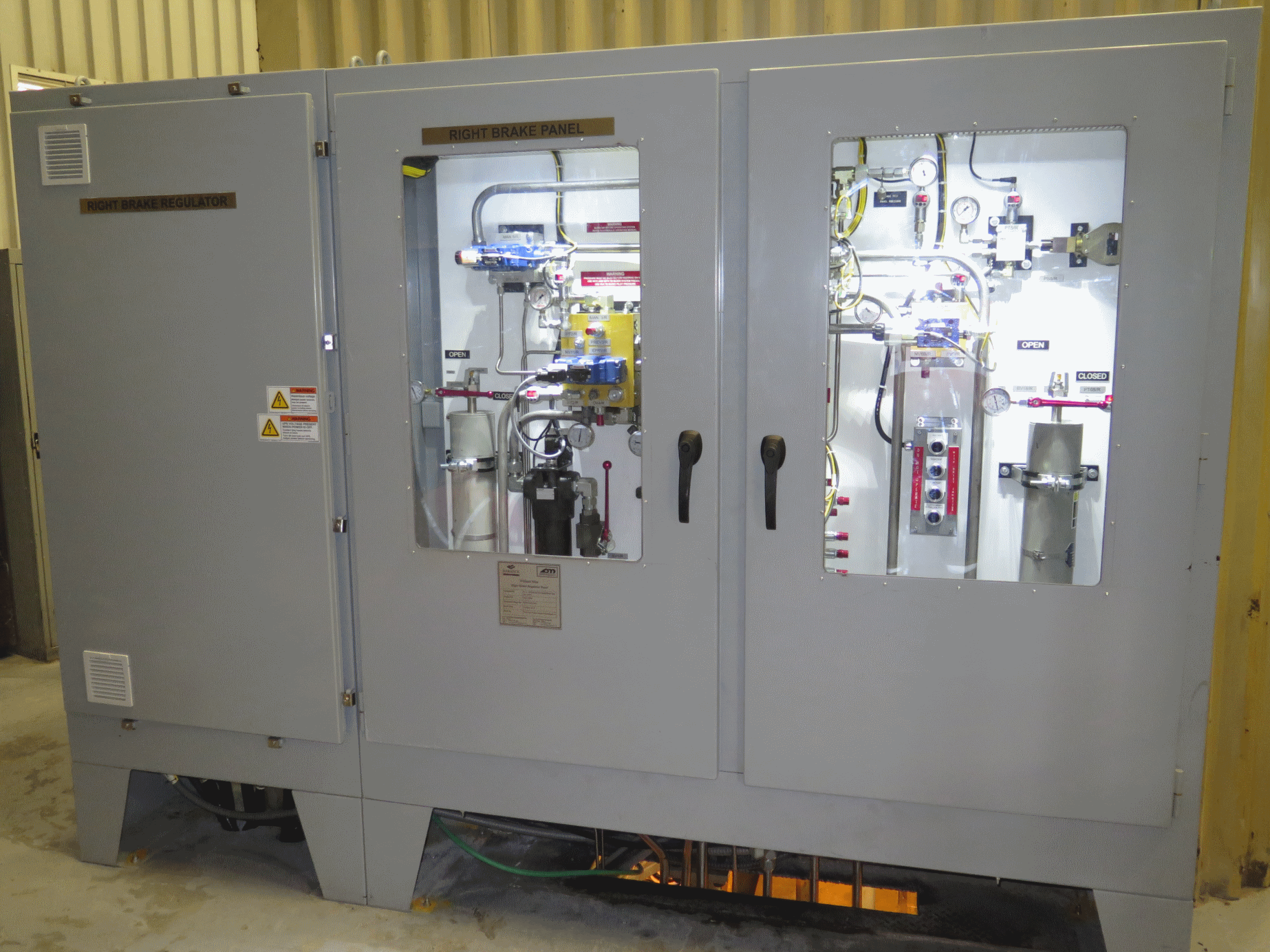

The system was custom manufactured on separate containment skids to allow the system to be moved into the basement of the hoist room through existing access hatches. The tank included control and monitoring of oil temperature, levels and filtration.

Site support was provided during system installation to assist with tube routing, electrical integration into the existing control system as well as during set-up, commissioning and testing.

Hoist Bearing Lubrication Systems are only part of our available services, check out our other services here:

http://spencerengineering.com/services/